Our Products

What we do?

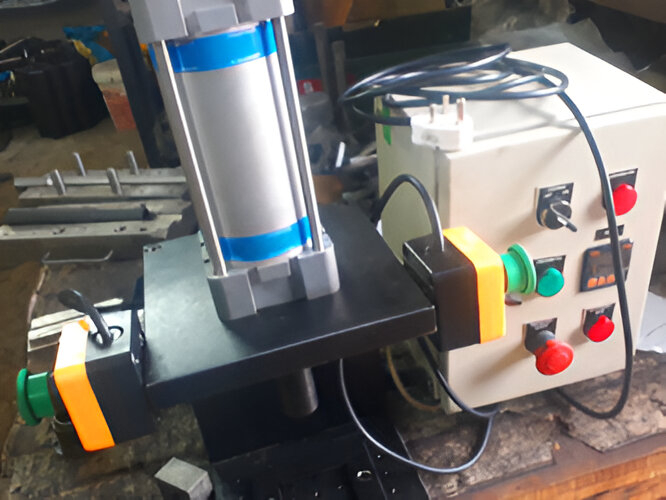

Rotating Fixture

A rotating fixture is a vital tool in precision manufacturing, designed to hold and rotate workpieces for various machining and assembly tasks.It allows for operations to be performed around the circumference of a part, or at specific angular positions, increasing efficiency and accuracy.

These fixtures are essential when dealing with cylindrical or complex shapes requiring consistent, repeatable movements.

The core function of a rotating fixture lies in its ability to securely hold the workpiece while enabling controlled rotation. This is achieved through a combination of clamping mechanisms and a rotation system, which can be manual or automated.

Fixtures

Fixtures are indispensable tools in manufacturing, serving as specialized workholding devices that precisely position and secure workpieces during various processes.

Their core function is to ensure consistent and repeatable results by accurately locating and holding the workpiece, preventing movement or vibration that could compromise accuracy or safety.

This stability is achieved through various clamping mechanisms and designs tailored to the specific operation and workpiece geometry. Fixtures streamline manufacturing by reducing setup times and minimizing the need for manual adjustments, thereby increasing efficiency and productivity.

Corobond Mixing

Corobond mixing is a critical process for preparing specialized coatings, primers, and bonding agents, often used in construction and industrial applications.

Typically involving two-component systems, comprising a resin and a hardener, precise mixing ratios are essential to ensure proper curing and optimal performance.

Adhering strictly to the manufacturer’s guidelines is crucial, as incorrect ratios can lead to compromised adhesion and product integrity. Thorough mixing, whether done manually or with mechanical mixers, ensures uniform distribution of the hardener throughout the resin, resulting in a consistent and reliable product.

Leather Strap Moulding

Leather strap molding is a process that shapes leather into specific strap forms using molds, primarily for creating consistent and durable straps for various applications.

Vegetable-tanned leather is often the preferred material, due to its pliability when dampened, which allows it to be effectively molded. The process begins with creating a pattern and mold, followed by preparing the leather by dampening or soaking it, sometimes with the addition of heat for increased flexibility.

The prepared leather is then pressed into the mold, often using clamps or presses, and allowed to dry completely, setting the desired shape. Once dry, the straps are trimmed, edged, and finished with dyes.